People ask me all the time: "Is logistics hard to learn?" It’s not the kind of question that gets a simple yes or no answer. If you’re thinking about jumping into logistics-whether you’re switching careers, fresh out of school, or just curious-you need to know what you’re actually signing up for. It’s not about memorizing shipping codes or memorizing warehouse layouts. It’s about solving real problems every single day, under pressure, with real money and real people on the line.

Logistics isn’t one thing-it’s a bunch of moving parts

Most people think logistics means driving trucks or managing warehouses. That’s part of it, sure. But logistics is the invisible system that gets your Amazon package to your door in two days, keeps supermarket shelves stocked, and ensures hospitals get life-saving medicines on time. It’s the coordination between suppliers, manufacturers, warehouses, transporters, customs agents, and retailers. If one piece breaks, the whole chain slows down-or stops.

Learning logistics means learning how these pieces fit together. You’ll need to understand inventory flow, route optimization, carrier contracts, demand forecasting, and compliance rules. It’s not magic. It’s math, logic, and people skills wrapped into one. And yes, it can feel overwhelming at first.

What makes logistics feel hard

Here’s the truth: logistics is hard because it’s messy. Unlike coding or accounting, where rules are clear, logistics deals with chaos. A truck breaks down. A port gets backed up. Weather shuts down a runway. A customer changes their order at the last minute. You don’t just follow a script-you adapt on the fly.

Many people struggle because they expect a textbook answer. There isn’t one. A route that works perfectly in Manchester might fail in Birmingham because of one-way streets and delivery windows. A warehouse layout that saves time in Leeds might cause bottlenecks in Glasgow. You learn by doing, not by reading.

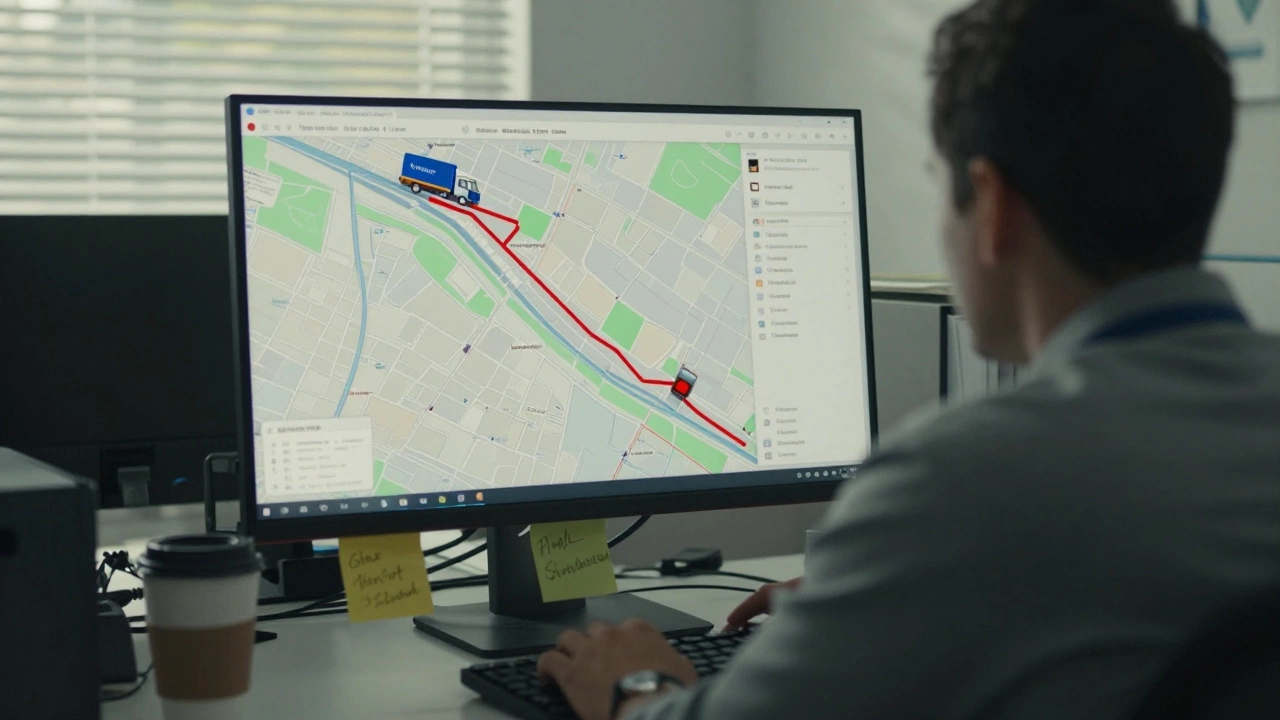

Another hurdle? The tools. You’ll use ERP systems like SAP or Oracle, TMS platforms like MercuryGate, and warehouse management software like Blue Yonder. If you’ve never used these before, it feels like learning a new language. But here’s the good news: you don’t need to be a tech wizard. Most companies train you on the software. What they really want is someone who can think clearly when things go wrong.

What makes logistics easier than you think

Here’s what nobody tells you: logistics is one of the most learnable fields out there. Why? Because everything is measurable. You can track delivery times, cost per shipment, warehouse picking accuracy, on-time performance. If you’re good with numbers and observation, you’ll pick it up fast.

Start with the basics: understand the difference between inbound and outbound logistics. Learn what a Bill of Lading is. Know what LTL and FTL mean. These aren’t fancy terms-they’re everyday language in the industry. You can learn them in a week with free online resources from the Chartered Institute of Logistics and Transport (CILT) or the UK’s Logistics UK.

And here’s the secret: you don’t need a degree. I’ve worked with warehouse supervisors who never went to university. I’ve seen dispatchers who started as warehouse packers and now run entire regional networks. What matters is reliability, attention to detail, and the ability to communicate clearly under pressure.

Real skills you actually need

Forget the idea that you need to be a genius. Logistics rewards practical skills, not academic credentials. Here’s what you really need to learn:

- Problem-solving under pressure-Can you find a new carrier when your usual one cancels at 3 a.m.?

- Attention to detail-One wrong zip code can delay a shipment by two days.

- Basic math-Calculating freight costs, load efficiency, fuel surcharges. No calculus needed.

- Communication-You’ll talk to drivers, customers, warehouse staff, and customs brokers. Being clear and calm matters more than being loud.

- Adaptability-Plans change. Constantly. If you hate surprises, this isn’t the field for you.

These aren’t skills you learn in a classroom. You learn them by shadowing someone, asking questions, and making small mistakes early-before they cost a company thousands.

Where to start if you’re new

If you’re starting from zero, here’s a realistic path:

- Get a job as a warehouse operative or delivery driver. You’ll see the whole process from the ground up.

- Ask questions. Why is this package routed this way? Why did this shipment get delayed?

- Take a free online course from FutureLearn or the CILT’s introductory modules. They cover supply chain basics in under 10 hours.

- Learn one software tool-start with Excel. Learn pivot tables, VLOOKUPs, and basic formulas. You’ll use them daily.

- Move into a coordinator role. That’s where the real learning begins.

Many logistics companies in the UK, like DHL, XPO, and DB Schenker, have graduate schemes and internal training programs. You don’t need to apply to a fancy university. Just show up, be reliable, and ask to learn.

Who struggles the most-and who thrives

People who do well in logistics are usually not the ones with the highest grades. They’re the ones who:

- Like figuring out how things work

- Don’t mind repetitive tasks if they have a clear purpose

- Stay calm when things go sideways

- Prefer action over theory

People who struggle are often those who expect everything to be neat and predictable. Logistics is the opposite. It’s a field where the best planners are the ones who expect the plan to fail-and have a backup ready.

If you’re the type who enjoys puzzles, fixing things, or managing chaos, you’ll thrive. If you need everything to be perfectly ordered before you can start, you’ll burn out.

Is it worth it?

Yes. Logistics is one of the most stable career paths in the UK right now. With e-commerce growing and supply chains becoming more complex, companies are desperate for people who understand how to move goods efficiently. Entry-level roles pay between £22,000 and £28,000. After three years of solid work, you can easily hit £40,000+ as a logistics coordinator or operations supervisor.

And unlike tech jobs that change every few years, logistics skills are timeless. The tools might upgrade, but the core problem-getting the right thing to the right place at the right time-won’t change.

It’s not glamorous. You won’t see your name on a TED Talk. But you’ll know that when someone gets their medicine on time, or their birthday gift arrives before the party, you made that happen. That’s the real reward.

Do I need a degree to work in logistics?

No. While a degree in supply chain management can help, most logistics jobs don’t require one. Many people start in warehouse or delivery roles and move up through experience. Employers value reliability, problem-solving, and hands-on knowledge more than academic credentials.

How long does it take to learn logistics?

You can learn the basics in 3 to 6 months with consistent effort-understanding shipping documents, basic routing, and warehouse workflows. But mastering logistics takes years. It’s like learning to drive: you can get a license quickly, but becoming a skilled driver takes real-world experience. Most professionals say it takes 3-5 years to feel truly confident.

Is logistics a good career for someone who hates computers?

You don’t need to love computers, but you do need to use them. Most logistics roles require basic software skills-Excel, tracking systems, communication tools. If you’re willing to learn those, you’ll be fine. Many people who thought they "hated tech" ended up thriving once they saw how the tools helped them solve real problems faster.

What’s the biggest mistake beginners make?

Trying to fix everything at once. Newcomers often think they need to understand every part of the supply chain immediately. That’s impossible. Start with one area-like inbound deliveries or warehouse picking-and master that. Once you’re confident there, move to the next. Slow, steady progress beats rushing.

Can I switch into logistics from another industry?

Absolutely. People come from retail, hospitality, construction, even the military. The skills that matter-organization, communication, reliability-are transferable. Many logistics companies actively recruit from other sectors because they value people with real-world experience and a strong work ethic.

Final thought: It’s not about being smart-it’s about being steady

Logistics isn’t hard because it’s complicated. It’s hard because it’s relentless. There’s no day off when the world stops shipping. But if you’re the kind of person who shows up, pays attention, and keeps showing up-even when things go wrong-you’ll not only learn it, you’ll be one of the few who actually keep it running.